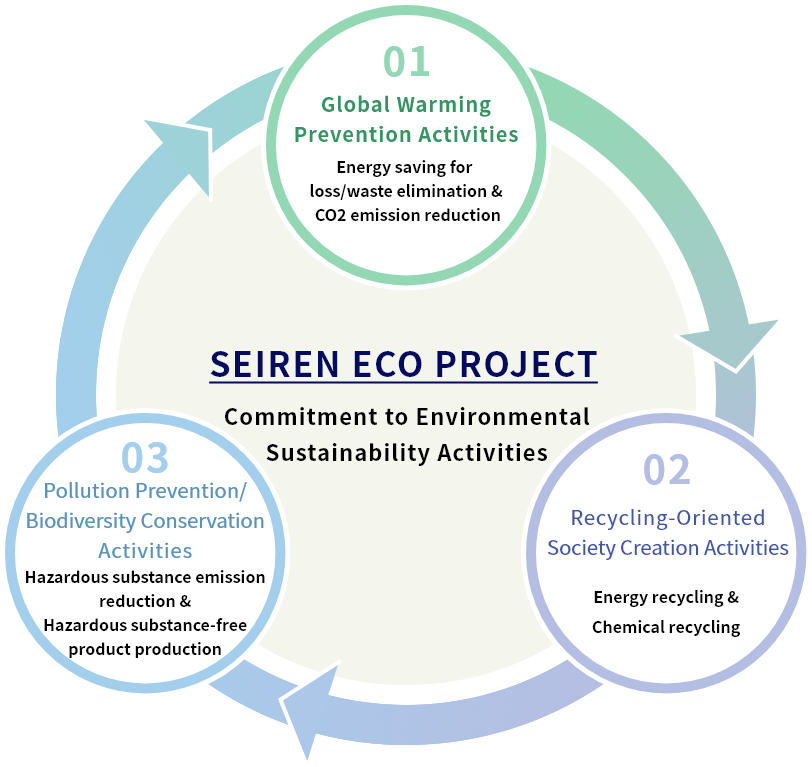

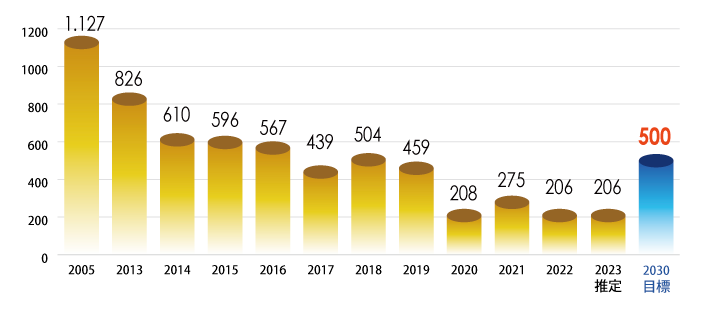

Global Warming Prevention Activities

Committing to prevention of global warming through energy saving activities

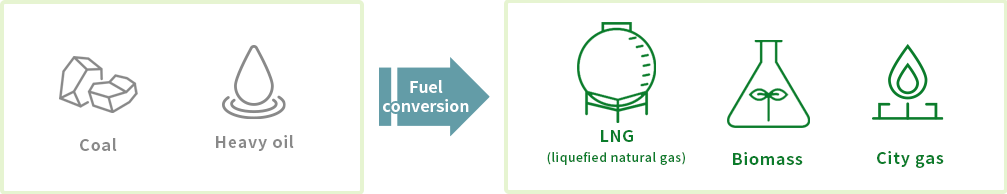

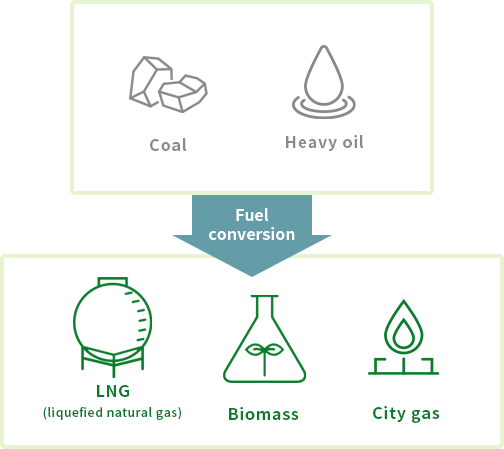

The Seiren Group is committed to reducing CO2 emissions by fuel conversion from coal and heavy oil to liquefied natural gas (LNG) and biomass as well as manufacturing process streamlining, loss/waste reduction and energy saving equipment introduction.

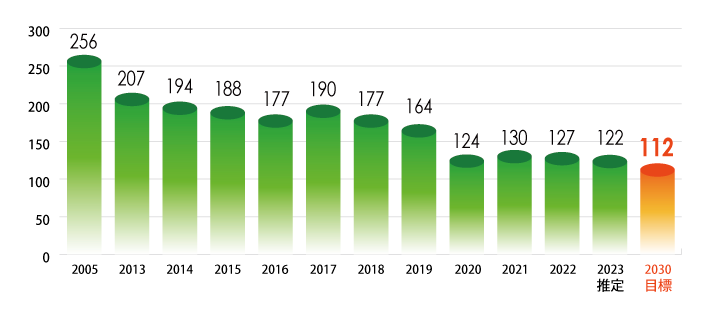

Transition of CO2 emissions (thousand tons-CO2)

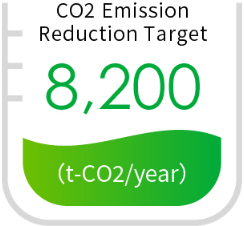

Katsuyama Plant Biomass Boiler

Put into operation in October 2016

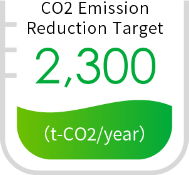

KB Seiren Hokuriku Synthetic Fiber Plant LNG Boiler

Put into operation in January 2016

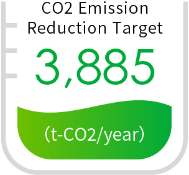

KB Seiren Nagahama Plant Once-Through Boiler

Put into operation in December 2008

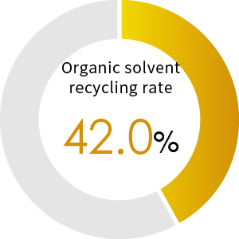

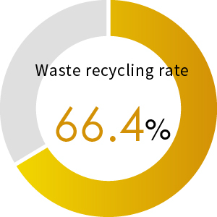

Recycling-Oriented Society Creation Activities

Committing to waste reduction aiming at creating a recycling-oriented society

The Seiren Group is committed to contributing to creation of a recycling-oriented society by recovering waste emitted or discharged from its facilities and regenerating and reusing it as an important resource to the maximum extent possible.

Nitta Production Site Organic Solvent Recovery Equipment

Nitta Production Site Organic Solvent Recovery Equipment

(Put into operation in November 1999)

(Put into commercialization in 2007)

Major Activities for Promoting Waste Recycling

- Recycling of organic solvent from waste resin

- Recovery of rare metal from liquid/plastic waste to convert it into a valuable resource

- Sorting of plastic/vinyl waste to convert it into a valuable resource

- Conversion of plastic waste into a solid fuel

- Sorting of metal waste to convert it into a valuable resource

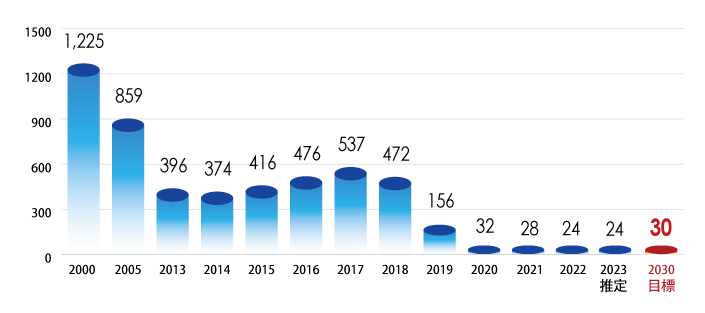

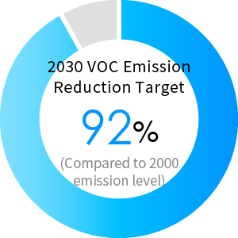

Pollution Prevention/Biodiversity Conversion Activities

Committing to chemical substance content control and emission reduction to conserve biodiversity

To comply with multiple laws and regulations requiring us to control chemical substances contained in our products, we at the Seiren Group have formulated "Green Procurement Guideline" to establish a system for control of chemical substance content in chemicals and materials used in our production not only to secure the safety of our employees, but also to meet our customers' requirements in this regard.

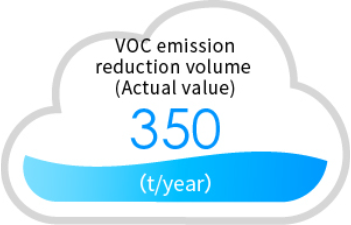

In addition, we are committed to reducing emissions of VOC and PRTR (Pollutant Release and Transfer Register) substances from our facilities for reduction of environmentally hazardous waste to prevent pollution and conserve biodiversity.

VOC Emission Volume into Atmosphere (tons)

Futsukaichi Production Site Rotary Regenerative Thermal Oxidizer

Rotary Type Regenerative Thermal Oxidizer

(Introduced into Futsukaichi Production Site in January 2006)

Nitta Production Site Catalytic Oxidizer